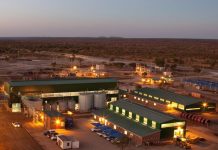

BULAWAYO – Gold output at How Mine in Bulawayo rose by 59% in 2021 as the mine benefitted from a capital injection and an improvement in mining standards. عدد قوارير البولينج

An increase in capital expenditure, which was used to acquire new mining equipment and to deepen the shaft, saw the company recording higher gold production, according to Kimbton Chiota, Managing Director of Bulawayo Mining Corporation (BMC), the holding company of How Mine. الفرق المتأهلة ليورو 2023

“This improved performance is on the back of a capital injection of US$5 million for the shaft sinking project, which opened up new mining areas. This project was commissioned in the last quarter of the year 2020,” Chiota said.

Gold production was 30 381 ounces, more than the 28 766 ounces that the company had budgeted for the year 2021.

Chiota was speaking as the mine received International Standards Organisation (ISO) recertification from the Standards Association of Zimbabwe. The ISO certification recognises global standards in factors such as occupational health and safety, environment protection, as well as management efficiencies.

According to Chiota, How Mine is expanding operations to further ramp up production.

“The mine is currently carrying out exploration, both on surface and underground, in order to open up the resource base for expansion,” Chiota added. “We remain focused on contributing towards the Government’s target of a US$12 billion mining industry by the year 2023.”

As part of the push for improved mining standards, How Mine acquired technology such as the rock mechanic GPR scanner. This technology allows the mine to scan rock formations and anticipate any safety risks. This has increased efficiencies and resulted in a sharp drop in injuries at work.

Due to improved efficiencies, the average cost per tonne milled was US, better than the US that the company had set as the target for the year. الباصره

Said Chiota: “These ISO standards have helped the company thrive through constant changes in the operating environment. BMC will therefore continue committing itself to internationally recognized standards.”

Eve Gadzikwa, director-general of SAZ, commended BMC for pursuing ISO standards, despite the difficult operating environment. She urged companies to maintain international standards, even when the environment is uncertain.

“You did not let the difficulties of the past two years force you to abandon certification,” Gadzikwa said.

BMC is a subsidiary of the Metallon Corporation.